Practix OK-16 CP Rotary Sublimation Press 128" Cut/Parts/Model

MSRP: $107,100.00

MSRP does not include ink, shipping, installation or training.

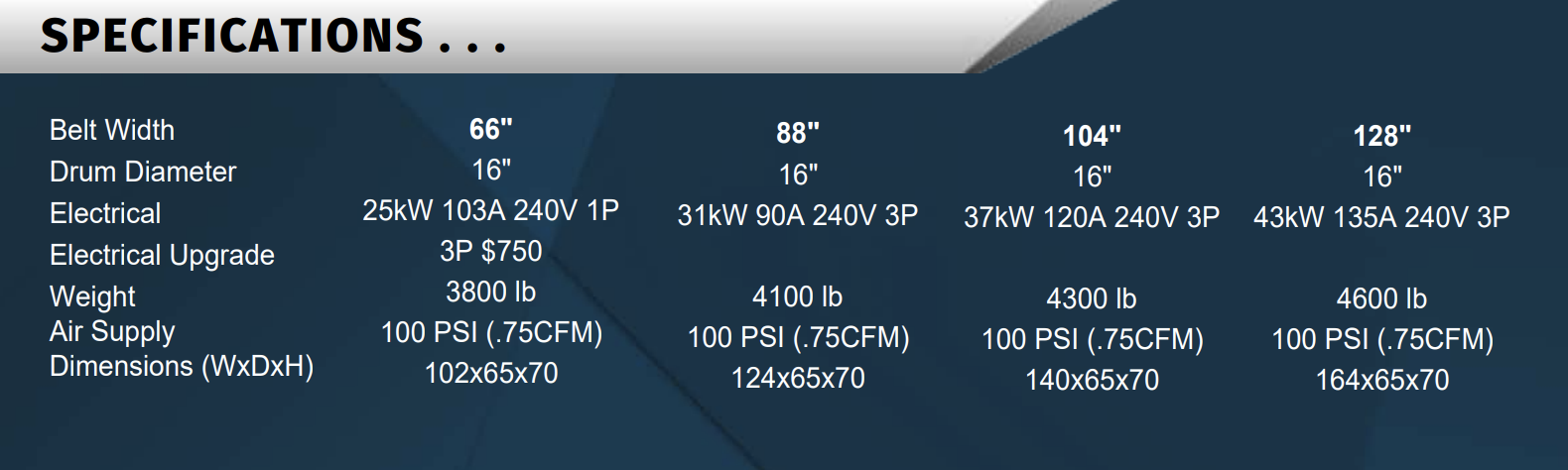

The Practix OK-16CP Rotary Press is available in 66”, 88”, 104” and 128” wide printable widths. The 16’ diameter oil filled steel encased drum offers 240 degrees of heat contact required for the sublimation heat transfer process. This drum size equates to an increased production speed of 230 feet per hour when running at a 40 second dwell time. Dwell time can easily be increased or decreased to accommodate the substrates heat transfer needs. Changing of the setting is easily performed on the large touch screen pad, and all settings can be saved for future production runs.

It is in APC’s best interest to use the technical specifications that any manufacturer includes with equipment. However, as specialists, we are determined to provide our customers and clientele with the most relevant and beneficial information about any product. We look forward to consulting and strategizing the best possible solution for you and your business. Let our experience be the difference in your experience.

Features & Benefits :

- 16” Oil filled encased diameter drum for high speed production

- 7″ touch screen interface of all mechanical functions provides intuitive user control and savable settings ensures consistent production

- Program for save settings

- Digital speed controller

- Automatic belt tracking system

- Three unwind and three rewind with pneumatic tension

- Pressure operated paper tension controls

- Three-inch chucks for all unwind and rewind shafts

- Reversing capability

- Safety systems (emergency stops and hand protection at entry)

- Automatic cool down and start up controls